👨🎓 About Me

I am currently focusing on TPMS lattice structure, Mechanical metamaterials and Additive manufacturing, as I pursue my Bachelor’s degree in Mechanical design, manufacture & its automation at the School of Transportation and Logistics Engineering, Wuhan University of Technology.

I have been awarded the Second-class Scholarship twice, in 2022 and 2023, and was hornored as one of the “Top Graduates of the Class of 2024” at my school.

My research journey began with the structural design of Triply period minimal surfaces(TPMS) and additive manufacturing when I was a sophomore. I held the belif that additive manufacturing can significantly shape the development of global economy, as this technique allows for production of architectures with extremely complicated shapes using fewer raw materials.

You can find my CV here: Di Lin’s CV.

⚙️ Projects

TPMS_Scaffold_Generator: A Scaffold-Structure Generator Based on Triply Periodic Minimal Surfaces

Date: 03/2022-03/2024

Role: Principal Investigator, WUT

Team Members: Di Lin, Cong Zhang, Xiyong Chen, Nannan Wang, Lei Yang*.

Description:

- Our team developed the TPMS_Scaffold_Generator, a software tool designed to generate various TPMS lattice structures. This tool enables researchers to conduct comprehensive investigations into the geometrical, mechanical, thermal, and vibrational properties of these structures.

- Our research focused on the compressive mechanical behavior of Ti-6Al-4V Fischer-Koch TPMS lattice structures with different gradients, fabricated using Laser Powder Bed Fusion (LPBF). Additionally, I introduced an innovative design for TPMS lattice structures, termed multi-symmetrical TPMS scaffolds with varying orientations.

Exceptional shape memory effect and superelasticity of ultra-light TPMS lattice sturctures fabricated by laser powder bed fusion

Duration: January 2023 - Present

Role: Principal Investigator, WUT

Contributors: Di Lin, Lei Yang*, Yunlong Ren, Mengying Chen, Siqi Wu, Hui Qiao, Chunze Yan and Yusheng Shi.

Brief: This research focuses on the fabrication and mechanic analysis of ultra-light Gyroid TPMS lattice structures using Laser Powder Bed Fusion (LPBF). The project highlights significant findings in shape memory effect and superelasticity.

- Manufacturing Fidelity: Employed VGSTUDIO MAX 3.4 to examine manufacturing fidelity, comparing high and low energy density parameters.

- Mechanical Properties Analysis: Conducted uniaxial compressive experiments on LPBF-fabricated specimens, systematically analyzing their compressive mechanical properties and behavior.

- Deformation Mechanics: Utilized finite element analysis to reveal the deformation mechanics of ultra-light Ni-Ti Gyroid TPMS lattice structures.

Multicell interlacing IWP lattice metamaterials with superior low-frequency vibration isolation performance fabricated by laser powder bed fusion

Duration: June 2023-Present

Role: Co-First author, supervised by Prof. Lei Yang and Assoc. Prof. Cong Zhang, WUT

Contributors: Mengying Chen1, Di Lin1, Lei Yang*, Cong Zhang, Hui Qiao, Liu He, Yunlong Ren, Chunze Yan and Yusheng Shi.

Brief: This research aims to develop and evaluate triply periodic minimal surface (TPMS) multi-cell interlacing metamaterials for enhanced vibrational isolation.

- Design and Model Generation: Designed and generated multicell interlacing IWP lattice models using MATLAB.

- Manufacturing and Experimental Responsibilities: Conducted quasi-static uniaxial compressive experiments and oversaw the fabrication of specimens using Laser Powder Bed Fusion (LPBF).

- Morphological Analysis: Performed morphological analysis of the surface features of samples and powders using Scanning Electron Microscopy (SEM).

- Vibrational Isolation Research: Assisted in the investigation of the vibrational isolation properties of multi-cell interlacing IWP lattice structures.

Mechanical properties and crack propagation of twin-oriented NiTi TPMS structures fabricated by laser powder bed fusion

Duration: anuary 2023 - Present

Role: Co-First Author, supervised by Prof. Lei Yang, Wuhan University of Technology (WUT)

Contributors:Yunlong Ren1, Di Lin1, Lei Yang, Hejiang Xu, Dianyu Tang, and Siqi Wu

Brief: This study investigates the mechanical properties of Ni-Ti Gyroid TPMS lattice structures with varying orientations and their impact on crack propagation control.

- Design of 3D Models: Designed 3D models of multi-symmetrical Gyroid TPMS lattice structures with different orientations using triangular implicit functions.

- Deformation Mechanics Analysis: Utilized the finite element method (FEM) to analyze the deformation mechanics of the structures.

- Experimental and Fatigue Analysis: Assisted in conducting uniaxial compressive experiments and analyzing the fatigue properties of the lattice structures.

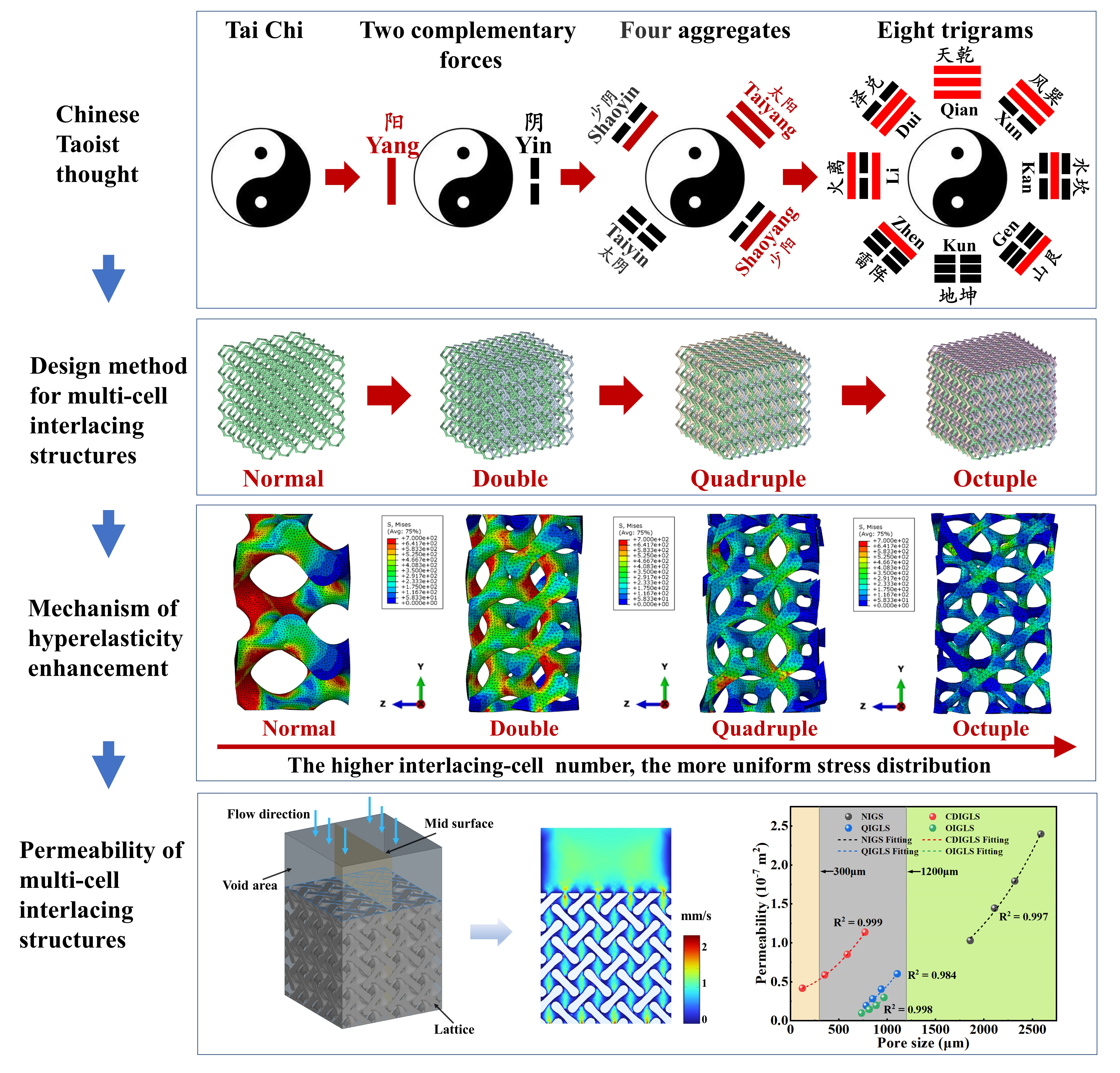

Mechanical properties and permeability characteristic of laser powder bed fused multicell interlacing Gyroid TPMS metallic biomaterials.

Date: 05/2024 - Present

Role: Principal Investigator, supervised by Prof. Lei Yang, WUT

Researchers: Di Lin, Yang Lei

Brief: This research aims to develop and evaluate triply periodic minimal surface (TPMS) multi-cell interlacing metamaterials for enhanced vibrational isolation.

- Inspiration and Design:

- Inspired by Chinese Taichi.

- Utilized advanced coding techniques to design and generate multicell interlacing Gyroid TPMS lattice structures.

- Research Objectives:

- 1.Mechanical Properties:

- Investigate the compressive mechanical properties of the lattice structures.

- Methods: Uniaxial compression tests and finite element analysis.

- Expected Completion: July 2024.

- 2.Permeability Characteristics:

- Elucidate the permeability characteristics of the structures.

- Methods: Purpose-designed permeability test and laminar computational fluid dynamics (CFD) analysis using COMSOL Multiphysics software.

- 1.Mechanical Properties:

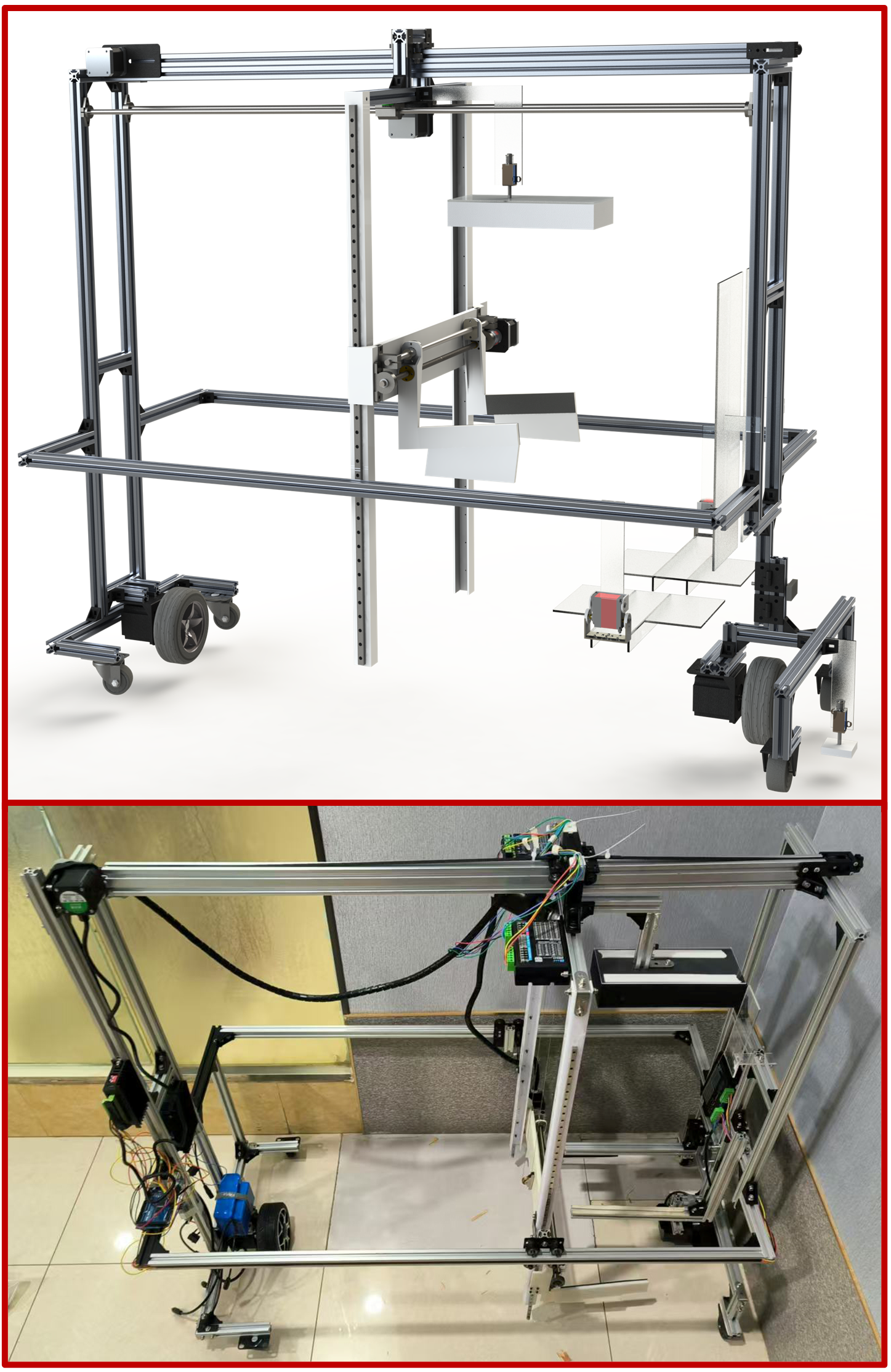

[Strength Verification and Mechanism Design of a Spiral Movement Device]

Date: 01/2023-08/2023

Role: Participant, supervised by Prof. Hanbin Xiao, WUT

Researchers: Kang Xia, Ruihan Liu, Gan Liu, Di Lin, Haotian Wang

Brief:

- Utilized Abaqus simulation software to verify the structural strength of the Spiral Movement Device.

- Responsible for 3D modeling the elevating mechanisms.

- Implemented laser ranging to enable the identification function of the Spiral Movement Device.

- Oversaw the coding and fine-tuning processes using Arduino.

📝 Publications and Patents

- TPMS_Scaffold_Generator: A Scaffold-Structure Generator Based on Triply Periodic Minimal Surfaces, Di Lin, Cong Zhang, Xiyong Chen, Nannan Wang, Lei Yang, Additive Manufacturing Frontiers 2023

- Triply periodic minimal surface multi-cell interlacing metamaterials to achieve superior vibrational isolation. Di Lin, Lei Yang, Yunlong Ren, Mengying Chen, Siqi Wu, Hui Qiao, Chunze Yan and Yusheng Shi. (Ongoing work)

- Multicell interlacing IWP lattice metamaterials with superior low-frequency vibration isolation performance fabricated by laser powder bed fusion, Mengying Chen1, Di Lin1, Lei Yang*, Cong Zhang, Hui Qiao, Liu He, Yunlong Ren, Chunze Yan, and Yusheng Shi. (Under review by Additive Manufacturing)

- Mechanical properties and crack propagation of twin-oriented NiTi TPMS structures fabricated by laser powder bed fusion. Di Lin, Lei Yang, Hejiang Xu, Dianyu Tang, and Siqi Wu, (With editor of Composite Structures)

- Mechanical properties and permeability characteristic of laser powder bed fused multicell interlacing Gyroid TPMS metallic biomaterials. Di Lin, Yunlong Ren, Mengying Chen, Hejiang Xu, Lei Yang*. (Ongoing work)

- Fully automated trasporter for yard bridges, Di Lin, Kang Xia, Ruihan Sun, Haotian Wang. CN202321806345.7, 2023

🎖 Honors and Awards

- 2024.05 Top Graduates of the Class of 2024, WHUT

- 2023.8 First Prize in the “2023 Chinese University Students Mechanical Engineering Innovation and Creativity Competition - Mining Cup in Logistics Technology (Cranes).” Organized by the Chinese Mechanical Engineering Society, this national-level competition had a low award rate of fewer than 6.7%.

- 2022-2023 Sanhao (Student with Triple accreditations) Student, Wuhan University of Technology. Recognized for ranking in the top 12% in both academic performance and overall education at the university level.

- 2022-2023 Second-class Scholarship, Wuhan University of Technology. Awarded to students who are in top 6% of their class based on academic performance at the university level.

- 2021-2022 Sanhao (Student with Triple accreditations) Student, Wuhan University of Technology. Recognized for ranking in the top 12% in both academic performance and overall education at the university level.

- 2021-2022 Second-class Scholarship, Wuhan University of Technology. Awarded to students who are in top 6% of their class based on academic performance at the university level.

📖 Educations

- 2020.09 - 2024.06, Undergraduate, Wuhan University of Technology, Hubei

- 2017.09 - 2020.06, Shunde No.1 High School, Guangdong

👩🏫 Research Assistant

- 2022.02 - 2024.07, Research on the design of TPMS lattice sturctures and their mechanical properties, supervised by Prof. Lei Yang(杨磊).

- 2024.08 - 2025.08 (expected), Research on topology optimization of TPMS lattice sturctures and their mechanical properties, supervised by Prof. Yu Wang(王煜) GBU.